Mechanical

In today's society, the design services of industrial facilities are mainly in the direction of energy optimization.

This design is mainly presented in the following 2 sections:

Mechanical

The main purpose of this section is more in designing facilities and cooling and heating issues of industrial buildings and factories and entering into aerodynamic issues. The transfer of fluids from one point to another is also considered in this section.

Most of the cost of oil projects and power plants is spent on the purchase of facilities for various structures, and the engineers of this group try to optimize energy consumption to reduce costs by using the latest technology in the world.

The scope of activity of this section is as follows

Preparation of plans for mechanical facilities

Providing a calculation booklet on how to select water supply, sewerage, refrigeration, heating and air conditioning systems

- Checking the location of ducts and risers and exit ducts of mechanical facilities

Selecting and purchasing mechanical and installation tools and equipment based on the best quality and the most appropriate price and introducing it to the employer

Manufacture of screw compressors *

Making all kinds of oxygen generators *

Making all kinds of pumps *

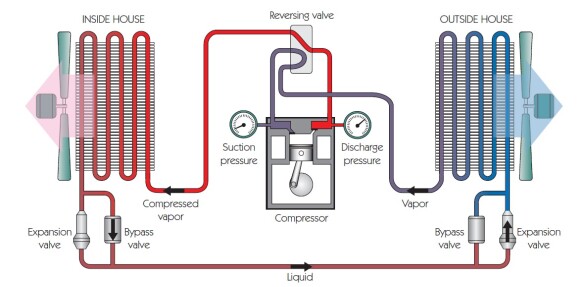

Manufacture of absorption chillers and compression chillers *

Construction of refrigerators from 10-5 thousand tons *

Manufacturing all kinds of industrial operators *

Manufacture of semi-industrial and industrial air conditioners *

Saneh Samim Arjmand Iranian Industries Knowledge based Company (Sairanian) is a professional manufacturer and supplier of various equipments for oil, gas, petrochemical, fire and electrical and mechanical industries. The company also provides services in the field of installation and air conditioning industry and has a brilliant history in the following areas:

Oil *

Gas *

Petrochemical *

Military and armaments industries *

Facilities and infrastructure *

Sairanian is a supplier and service provider of various heating and refrigeration systems

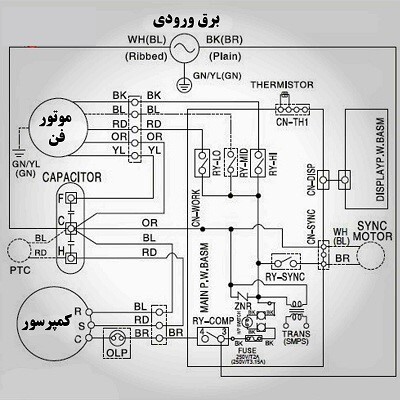

Types of window air conditioners

Hot and cold *

60 Hz *

Capacity 18,000 to 24,000 *

Compressor type: Rotary *

Compressor temperature tolerance: T3 *

Power supply: 220-240VAC *

Procurement, repair and supply of a variety of reputable brands *

Comes with warranty *

best quality

Best price

warranty and after-sales service

With years of experience and expertise, we are proud to offer the best in accordance with national and international standards. Obtaining the quality certificate of raw materials from contractors, presenting the quality assurance certificate of production and providing technical inspection during the production process to the employer are the distinguishing features of Sairanian.

Types of compression chillers *

Types of absorption chillers *

Types of hygienic air conditioners *

Clean room *

Types of refrigeration systems *

Gas

Military and armaments

Oil

Petrochemical

Facilities and infrastructure

Manufacturer of hygienic air conditioners for clean rooms

Manufacturer and supplier of various types of industrial air conditioning systems

Designer, manufacturer and supplier of various types of industrial pumps with special applications

Design and construction of clean rooms

Repair, maintenance and commissioning of all types of absorption and compression chillers

Repair, maintenance and commissioning of various compressed air supply systems

Commissioning and construction of refrigerators and sub-zero refrigeration systems

Supply and distribution of parts of refrigeration systems